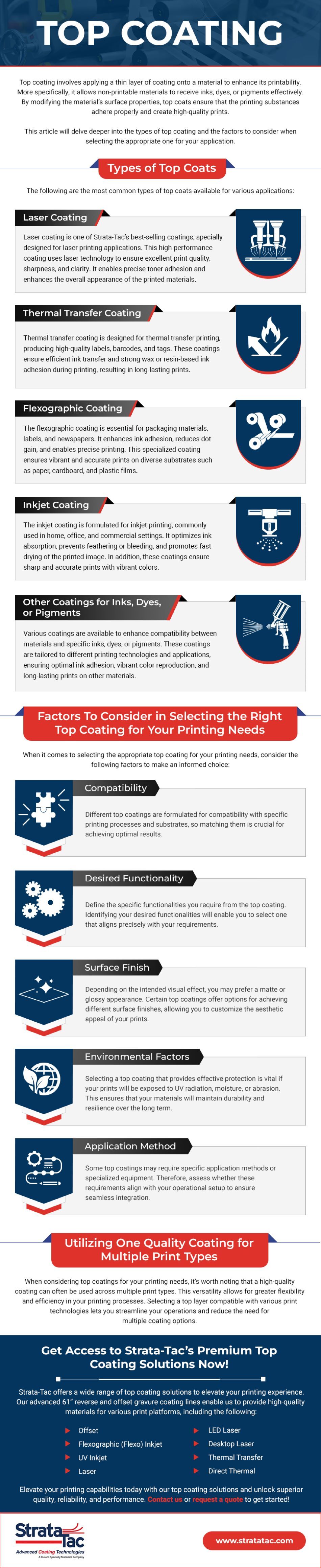

Top Coating

Top coating involves applying a thin layer of coating onto a material to enhance its printability. More specifically, it allows non-printable materials to receive inks, dyes, or pigments effectively. By modifying the material’s surface properties, top coats ensure that the printing substances adhere properly and create high-quality prints.

This article will delve deeper into the types of top coating and the factors to consider when selecting the appropriate one for your application.

Types of Top Coats

The following are the most common types of top coats available for various applications:

Laser Coating

Laser coating is one of Strata-Tac’s best-selling coatings, specially designed for laser printing applications. This high-performance coating uses laser technology to ensure excellent print quality, sharpness, and clarity. It enables precise toner adhesion and enhances the overall appearance of the printed materials.

Thermal Transfer Coating

Thermal transfer coating is designed for thermal transfer printing, producing high-quality labels, barcodes, and tags. These coatings ensure efficient ink transfer and strong wax or resin-based ink adhesion during printing, resulting in long-lasting prints.

Flexographic Coating

The flexographic coating is essential for packaging materials, labels, and newspapers. It enhances ink adhesion, reduces dot gain, and enables precise printing. This specialized coating ensures vibrant and accurate prints on diverse substrates such as paper, cardboard, and plastic films.

Inkjet Coating

The inkjet coating is formulated for inkjet printing, commonly used in home, office, and commercial settings. It optimizes ink absorption, prevents feathering or bleeding, and promotes fast drying of the printed image. In addition, these coatings ensure sharp and accurate prints with vibrant colors.

Other Coatings for Inks, Dyes, or Pigments

Various coatings are available to enhance compatibility between materials and specific inks, dyes, or pigments. These coatings are tailored to different printing technologies and applications, ensuring optimal ink adhesion, vibrant color reproduction, and long-lasting prints on other materials.

Factors To Consider in Selecting the Right Top Coating for Your Printing Needs

When it comes to selecting the appropriate top coating for your printing needs, consider the following factors to make an informed choice:

Compatibility

Different top coatings are formulated for compatibility with specific printing processes and substrates, so matching them is crucial for achieving optimal results.

Desired Functionality

Define the specific functionalities you require from the top coating. Identifying your desired functionalities will enable you to select one that aligns precisely with your requirements.

Surface Finish

Depending on the intended visual effect, you may prefer a matte or glossy appearance. Certain top coatings offer options for achieving different surface finishes, allowing you to customize the aesthetic appeal of your prints.

Environmental Factors

Selecting a top coating that provides effective protection is vital if your prints will be exposed to UV radiation, moisture, or abrasion. This ensures that your materials will maintain durability and resilience over the long term.

Application Method

Some top coatings may require specific application methods or specialized equipment. Therefore, assess whether these requirements align with your operational setup to ensure seamless integration.

Utilizing One Quality Coating for Multiple Print Types

When considering top coatings for your printing needs, it’s worth noting that a high-quality coating can often be used across multiple print types. This versatility allows for greater flexibility and efficiency in your printing processes. Selecting a top layer compatible with various print technologies lets you streamline your operations and reduce the need for multiple coating options.

Get Access to Strata-Tac’s Premium Top Coating Solutions Now!

Strata-Tac offers a wide range of top coating solutions to elevate your printing experience. Our advanced 61” reverse and offset gravure coating lines enable us to provide high-quality materials for various print platforms, including the following:

- Offset

- Flexographic (Flexo) Inkjet

- UV Inkjet

- Laser

- LED Laser

- Desktop Laser

- Thermal Transfer

- Direct Thermal

Elevate your printing capabilities today with our top coating solutions and unlock superior quality, reliability, and performance. Contact us or request a quote to get started!